Punch Your Battery Materials Cleanly without Burrs or Peeling

Handheld Electrode Punch

Punching cathode and anode electrode materials

for prototype coin cell batteries,

Conducting precise area weight measurements

and sample processing for quality control ――

This is the standard tool that has supported

battery development worldwide for over 20 years.

REASONS

Why NOGAMI’s Handheld Punch stand out

Overwhelming Processing Performance

No burrs, sagging, or peeling.

Standard tool with 20 years of experience.

High Usability

Light weight and compact.

Easy to punch out your material in the glovebox.

Durable and Long-lasting

Highly durable and long-lasting, trusted by users around the world.

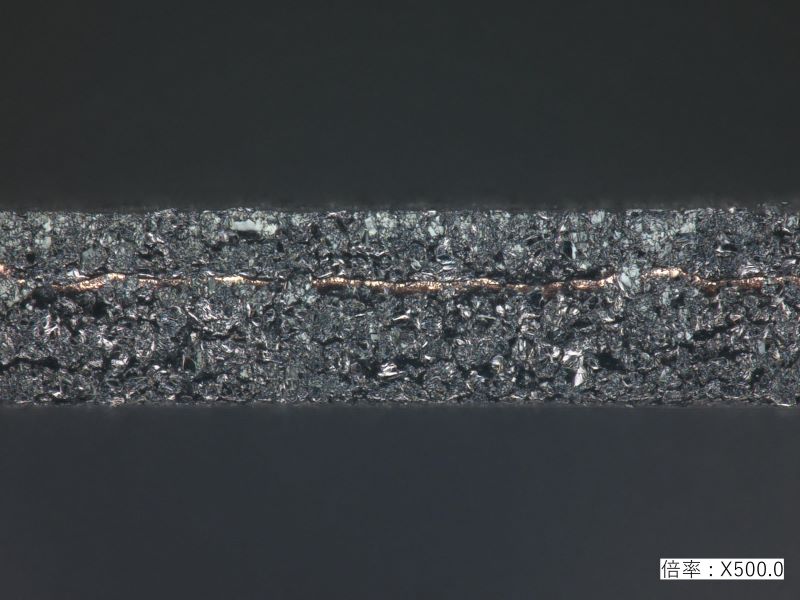

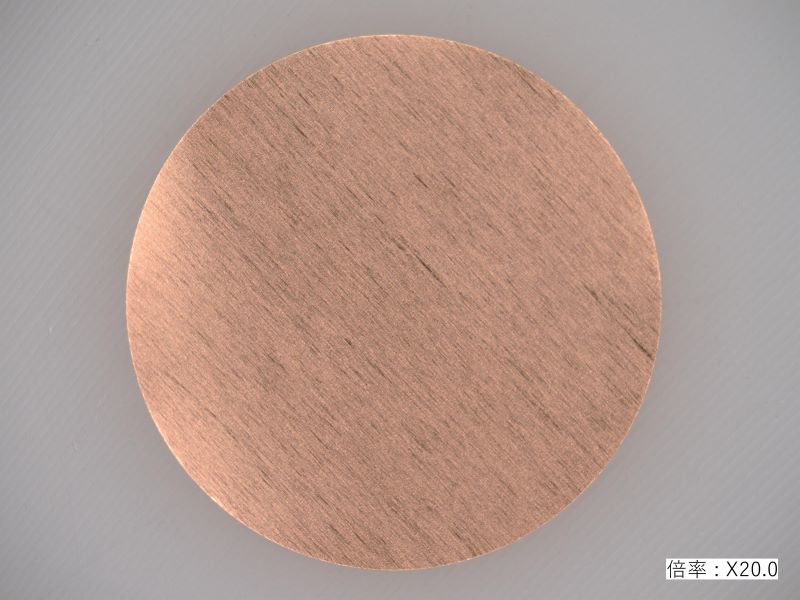

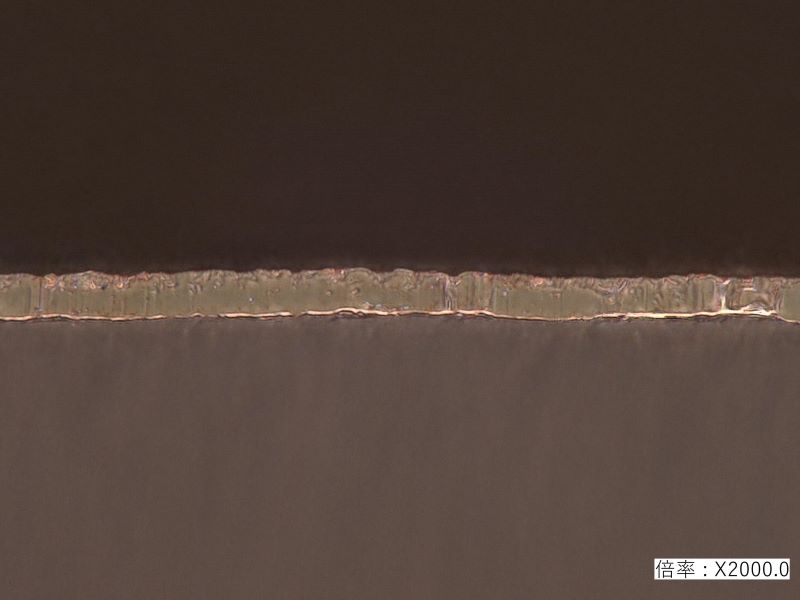

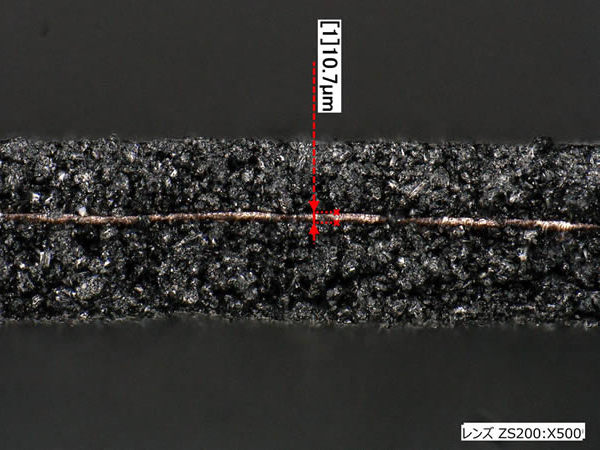

PRECISION CUTTING

Overwhelming Processing Performance

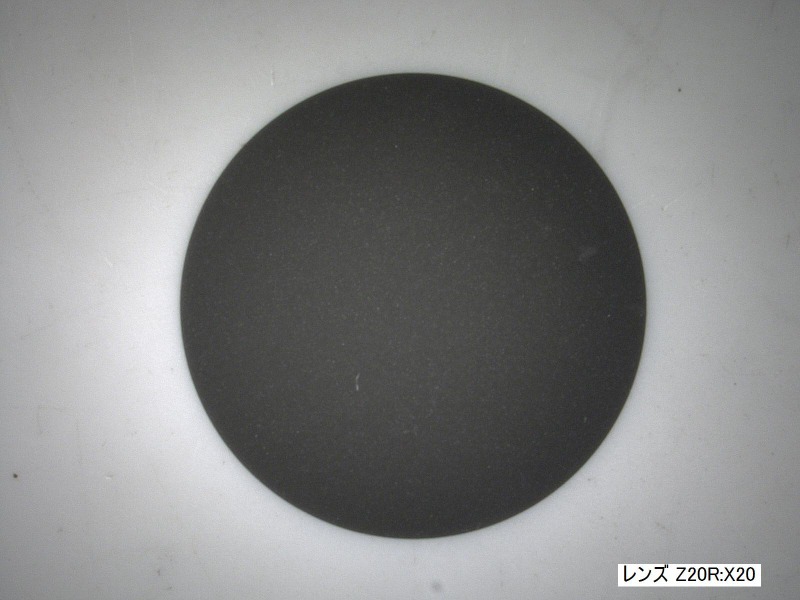

Entire top view [ x20 ]

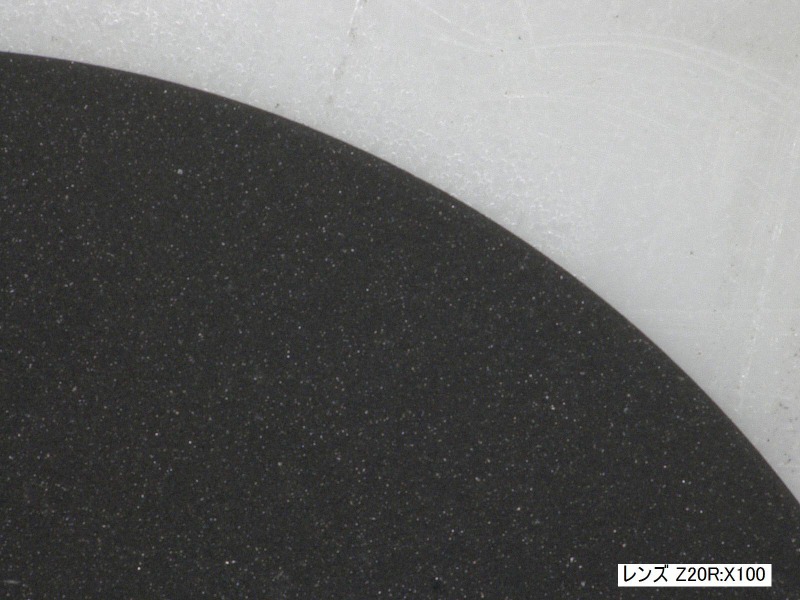

Top view of a certain part [ x100 ]

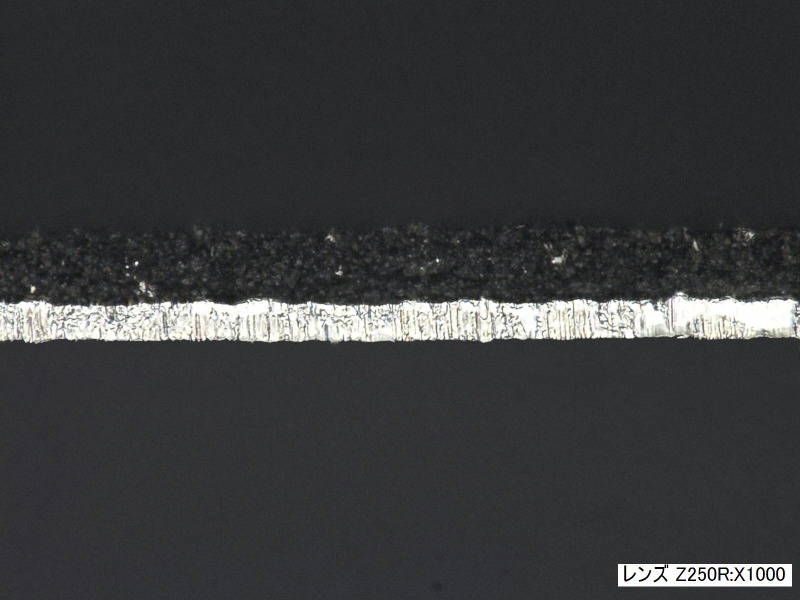

Cross sectional view [ x1000 ]

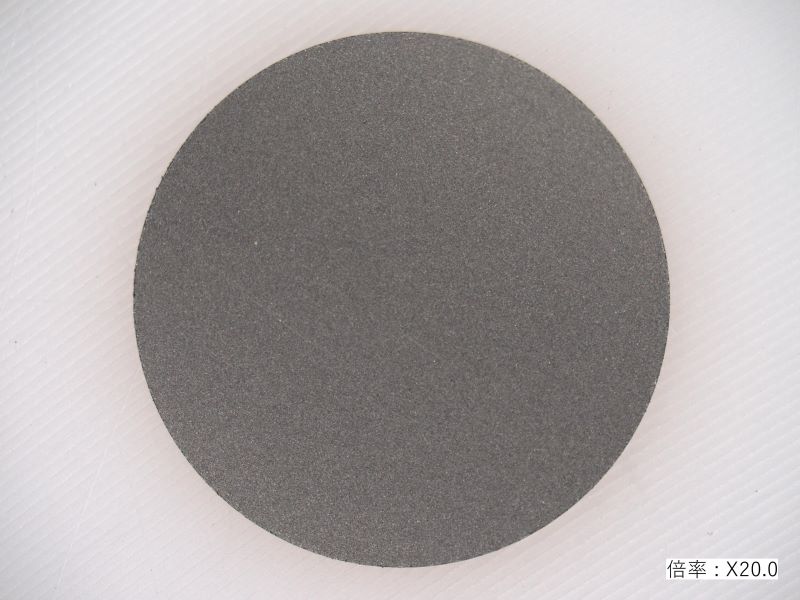

Entire top view [ x20 ]

Top view of a certain part [ x100 ]

Cross sectional view [ x500 ]

Entire top view [ x20 ]

Top view of a certain part [ x100 ]

Cross sectional view [ x2000 ]

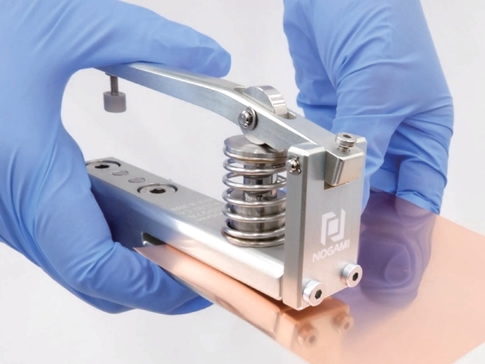

EASY TO HANDLE

High Usability

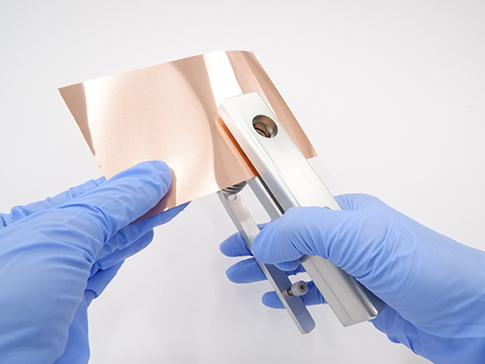

Easy for Anyone

You can punch out and eject your material with one hand

while visually checking the processing position.

It achieves processing performance and robustness

far superior to large stationary jigs in a handy size

that anyone can use.

Also, in the Glove Box

The ultimate compact design allows smooth operation

in any work environment.

It doesn’t take up much space in the glove box,

and you can work with no stress even when wearing thick gloves.

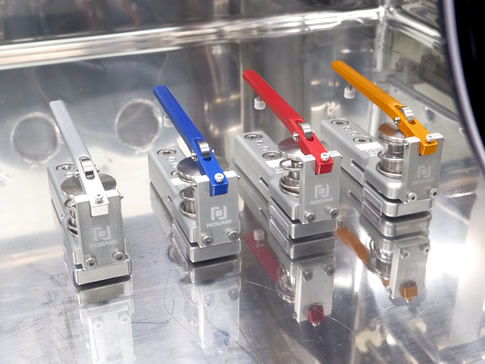

Specifications Identifiable

at a Glance

You can choose from four lever colors:

silver, blue, red, and gold.

By assigning a unique lever color to each product specification,

you can easily identify parameters such as

punching diameters (Φ14 mm, Φ15 mm, Φ 16mm, etc.)

and punch-die clearances (4 μm, 3 μm, 2 μm, etc.).

LONG LIFE

Durable and Long-lasting

Durable Blades,

Less Likely to Wear Out

The smooth, precise movement without any play between

the upper and lower blades minimizes wear and tear

on the tool after repeated use.

Even in dry environments, regular greasing extends their lifespan.

Maintenance is an easy task with the included specialized grease.

Restoring Sharpness

by Resharpening

Even if the blade edge wears down,

its sharpness can be restored by resharpening.

Even if rust or corrosion occurs after several years of use,

It is possible to restore the product to its original condition

by replacing only the necessary parts.

SPESIFICATION

Product Specifications

| Punching shape | Round / Square (and Rectangular) |

| Punching Size | Round : Φ1.00 to 26.00 mm Square : □1.00 to 22.00 mm |

| Opening* length | 45 mm (S-L) / 100 mm (For quality control) |

| Body Material | High-strength aluminum alloy |

| Blade Material | Alloy tool steel / Cemented carbide |

| Blade Coating | None / Special coated |

* Distance from the punch center to the end of the opening.

REVIEW

User Testimonials

USAGE

For Various Uses in Battery Development

Coin Cell Prototyping

Precision processing of cathode and anode electrode materials for coin cell battery prototypes

Handheld Electrode Punch Φ14/15/16 mm

Φ14/15/16 mm (common sizes for this application) [always in stock]

or any other sizes you want

Active Material Weight Measurement

Reduce data variation by processing samples with constant area and weight

Handheld Electrode Punch Φ10/11.28 mm

Φ10/11.28 mm (common sizes for this application) [always in stock]

or any other sizes you want

Quality control on mass production lines

Punching samples at a deep position from the side edge of the rolled material that is set on the mass production line

Handheld Electrode Punch F100mm for quality control

Long type with a length of 100 mm from the center of the punch to the edge of the opening

Any sizes you want [BTO]

Price

Price Samples

Please note that each price listed above is for the product only.

Shipping costs, banking commission, customs duties, etc. will be charged separately.

Frequently asked questions

FAQ

inquiry form

Catalog / Quote Request

![ハンドパンチ MLサイズ [ Φ10.01~18.00/□8.01~13.00 ]](https://www.nogami-gk.co.jp/wp-content/uploads/2023/08/handheld-punch_ml-size-1.jpg)

![ハンドパンチ Lサイズ [ Φ18.01~26.00/□13.01~22.00 ]](https://www.nogami-gk.co.jp/wp-content/uploads/2023/08/handheld-punch_l-size-1.jpg)