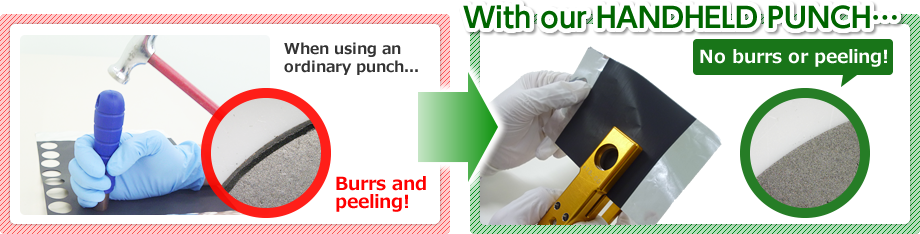

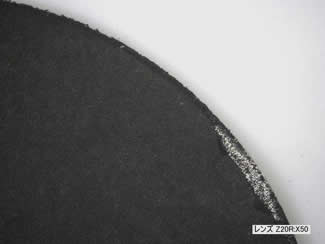

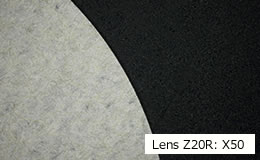

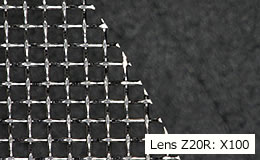

Thanks to ultra-precise finishing, this tool has extremely low

clearance and long service life with no burrs or deformation.

Can even handle foils (5µ and up) which are usually difficult to punch.

![]()